Welcome to the official website of Shenzhen Kaidexun Technology Co., Ltd.

-

contact number

contact number15013429139

-

Email address

Email address -

office hours

office hoursMon-Sat:9.00am to 18.00pm

Welcome to the official website of Shenzhen Kaidexun Technology Co., Ltd.

15013429139

Mon-Sat:9.00am to 18.00pm

Shenzhen Kaidexun Technology Co., Ltd.

Fixed line: 0755-28198006

Mobile: 15013429139

Fax: 0755-28169083

Mail: zhao.jh@kaidexun.com

Address: 2nd Floor, Building 18, Jiuwo Longjun Industrial Zone, Heping West Road, Dalang Street, Longhua New District, Shenzhen

after sales support

Fixed line: 0755-28198006

Mobile: 13823555655

Complaints and suggestions: 13823555655

In the current era of increasing digitalization and electronicization, manufacturing has always been regarded as the commanding heights of global economic competition, and countries have put it on their important agenda. With the implementation of innovation-driven development strategies, especially the Made in China 2025 Greater than According to the plan, the manufacturing industry is constantly improving the competitiveness of the real economy. At the same time, the concept of "Industry 4.0" is leading China's manufacturing industry to move towards a more intelligent "China Intelligent Manufacturing" development, followed by a new A round of scientific and technological revolution and industrial changes, these changes are giving birth to innovative breakthroughs.

Fields include biomedicine, new materials, new energy, large aircraft, aerospace engines, smart digital, etc., all of which are rapidly developing in the direction of unmanned and automated manufacturing and operation processes. However, with the rapid development of automated and unmanned production With the rise of the industry, some problems such as static electricity control have become increasingly prominent and need to be effectively dealt with. Therefore, the demand for industrial static electricity control solutions is growing day by day to ensure the reliability and quality of the production process.

Against this background, China's manufacturing industry is constantly progressing towards a more intelligent and automated direction. At the same time, issues such as static electricity control need to be solved to ensure efficient production and high-quality products. This trend will further promote industrial static electricity control solutions Program development to meet growing market demands.

ESD access control system definition

ESD access control system refers to a security access control system used to control and manage the access rights of electronic electrostatic sensitive equipment (ESD equipment). This system is designed to prevent ESD equipment from being affected by electrostatic discharge or other electrostatic sensitive issues to ensure their Operate normally and maintain a high level of reliability.

Function of ESD access control system

In many places, especially those where electrostatic protection areas (EPAs) have been set up, testing of electrostatic protective equipment (such as electrostatic shoes and electrostatic wristbands) is usually done using traditional, manually supervised methods, which is prone to problems. , it is difficult to ensure effective execution. This method is not only difficult to establish the trust of customers and management, but may also lead to potential electrostatic grounding problems. To address these shortcomings, an anti-static access control system was introduced, which provides a direct and effective solution scheme to ensure that employees have completed the necessary electrostatic grounding preparations before entering the EPA area. At the same time, this system is combined with a 3-roller gate as a control device for personnel passage, providing an orderly and civilized passage, effectively eliminating illegal Possibility of entry. In addition, in the event of an emergency, the gate lever can be quickly controlled to organize the evacuation of personnel. This comprehensive solution helps to improve the safety and management efficiency of EPA areas.

ESD access control system features

Application scope

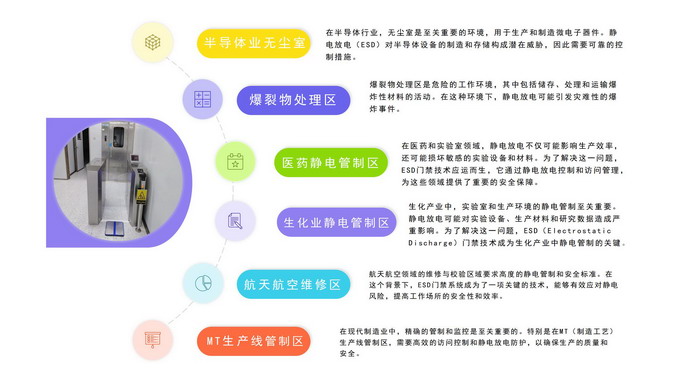

MT production line control area, semiconductor industry clean room, national defense and military static electricity control area, explosives disposal area, aviation equipment maintenance and verification area, medical experiment static electricity control area, high-end precision manufacturing, biochemical industry static electricity control area, and other needs Anti-static testing protection and other places

15013429139

2nd Floor, Building 18, Longjun Industrial Zone, No. 9, Heping West Road, Dalang Street, Longhua New District, Shenzhen City

zhao.jh@kaidexun.com